Follow us on Instagram

Follow us on YouTube

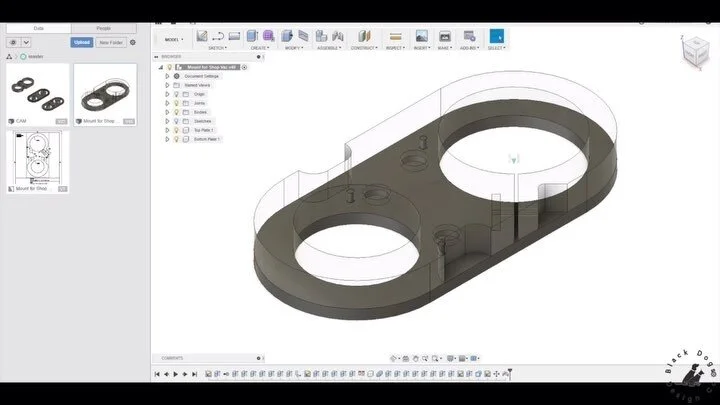

Getting ready to do some production runs of our CNC dust shoe but wanted to do some testing to figure out how to improve the surface finish so we can reduce the manual finishing. I tried a couple different finishing speeds, flame polishing, sanding, and buffing and the final results are very nice.

In this video I build the Flip Top Tool Cart from Fix This Build That. I had to make several modifications because my local home center didn't have the right parts but overall everything came together nicely and I'm super happy with the result.

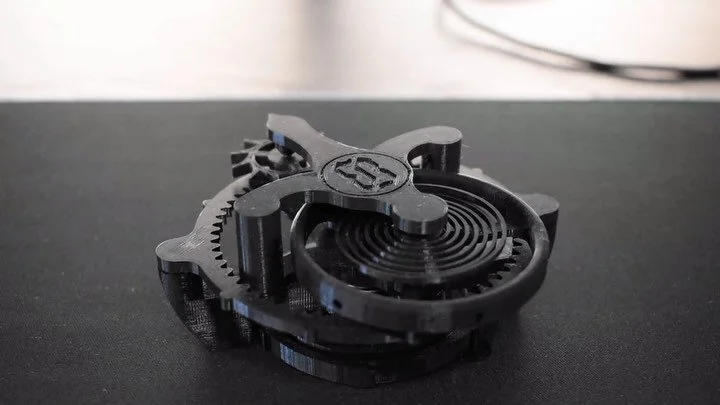

In this video we show how we make our acrylic dust shoes with a removable base. The removable base is aligned with magnets and alignment pins so that it is super secure and won't slide off during use.

My previous fixture for making branding iron handles worked well but required too much precision when drilling the alignment holes. I saw a great video by DP Make Stuff where he made one from some maker slide and I decided to make one as well.

Working on hard maple handles for the branding iron. This was my second test where I was really trying to optimize the tool paths and work on surface finish. Came out really well although I realized that I'm going to need a more flexible mounting jig design if I plan on making more of these.

I wanted to try to create custom cut foam inserts for shipping products so I picked up some closed cell and EVA foams for some tests. The closed cell foam (black) is a seat cushion and the EVA foam (gray) is an exercise mat.

Brass branding iron of our logo cut on my homemade 18x24 Solsylva CNC. All bits used are from Amana Tool, links below.